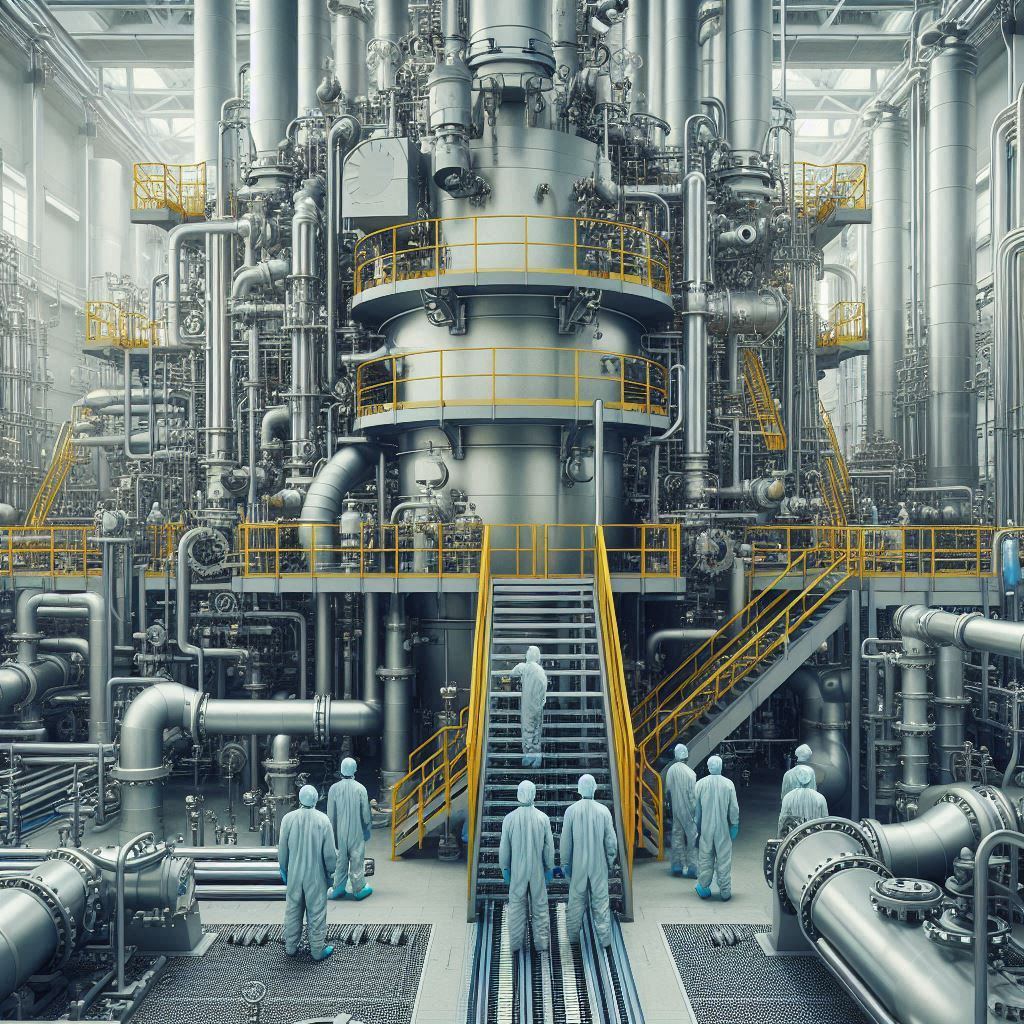

What is sewage treatment plant?

A sewage treatment plant is a facility designed to treat wastewater from households, commercial buildings, industries, and institutions to remove contaminants and pollutants before releasing the treated water back into the environment.

The process involves several stages including physical, biological, and chemical treatments to remove solids, organic matter, nutrients, pathogens, and other harmful substances from the sewage.

Types

Conventional Activated Sludge Plants: These are the most common type of STPs and typically consist of primary settling tanks followed by aeration tanks where microorganisms (activated sludge) treat the sewage by aerobic digestion. The treated effluent is then clarified in secondary settling tanks before discharge or further treatment.

Extended Aeration Plants: Similar to conventional activated sludge plants, extended aeration plants use aerobic digestion to treat sewage. However, they operate under low loading conditions with extended retention times, allowing for more efficient treatment without the need for primary settling tanks.

Sequential Batch Reactor (SBR) Plants: SBR plants are cyclic activated sludge systems where all treatment processes (fill, react, settle, decant) occur sequentially in a single tank. This allows for flexibility in operation and better control of treatment performance.

Rotating Biological Contactors (RBCs): RBCs consist of rotating discs or media that are partially submerged in sewage. Microorganisms attached to the media treat the sewage as it flows over the discs, providing aeration and biological treatment.

Process

The process for treating sewage in a Sewage Treatment Plant (STP) typically involves several stages to remove contaminants and pollutants from the wastewater. Here’s a simplified overview of the process:

- Preliminary Treatment:

- Screening: Large objects like sticks, rags, plastics, and other debris are removed using screens or bar racks.

- Grit Removal: Sand, gravel, and other heavy solids are settled out or removed to prevent damage to downstream equipment.

2. Primary Treatment:

- Sedimentation: The wastewater flows into a large tank where solids settle to the bottom forming sludge, while grease and oils float to the surface forming scum. These are removed for further treatment or disposal.

3. Secondary Treatment:

- Biological Treatment: The partially treated wastewater undergoes biological treatment where microorganisms (usually bacteria) break down organic matter into simpler substances. This can be done in various ways:

- Activated Sludge Process: Wastewater is aerated and mixed with activated sludge (microorganisms) in aeration tanks. The activated sludge digests organic matter, and then the mixture is settled in secondary clarifiers where the sludge settles out.

- Trickling Filter Process: Wastewater is sprinkled over a bed of rocks or plastic media covered with microorganisms. The organic matter is degraded by the microorganisms as the wastewater passes through the media.

- Rotating Biological Contactors (RBCs): Wastewater flows over discs or media with microorganisms attached, providing a large surface area for biological treatment.

4. Tertiary Treatment:

- Additional treatment processes such as filtration, advanced biological treatment, or chemical treatment may be employed to further remove nutrients (like nitrogen and phosphorus), pathogens, and other contaminants if required.

5. Disinfection:

- The treated wastewater is disinfected to kill remaining pathogens (bacteria, viruses, etc.) before it is discharged into the environment. Common disinfection methods include chlorination, ultraviolet (UV) radiation, and ozonation.

6. Sludge Treatment:

- Sludge produced during the treatment process undergoes further treatment to reduce volume and stabilize it for safe disposal or beneficial reuse. This may involve processes such as thickening, digestion, dewatering, and sometimes thermal treatment.

7. Effluent Discharge or Reuse:

- The treated wastewater, known as effluent, is discharged into receiving water bodies like rivers or oceans, or reused for non-potable purposes like irrigation, industrial processes, or groundwater recharge, depending on its quality and local regulations.

Importance

Protection of Water Bodies: STPs remove pollutants and contaminants from wastewater before it is discharged into rivers, lakes, oceans, or other water bodies. By treating sewage, STPs prevent the pollution of water sources, preserving aquatic ecosystems and ensuring a safe and sustainable water supply for various uses, including drinking water.

Public Health: Untreated sewage can contain harmful pathogens such as bacteria, viruses, and parasites, which pose serious risks to public health if released into the environment. STPs remove these pathogens through disinfection processes, reducing the spread of waterborne diseases and protecting human health.

Environmental Sustainability: STPs help maintain the ecological balance of aquatic ecosystems by reducing the input of nutrients (such as nitrogen and phosphorus) and organic matter into water bodies. Excessive nutrient levels can lead to eutrophication, which degrades water quality, harms aquatic life, and disrupts ecosystems. By treating sewage, STPs mitigate these environmental impacts.

Compliance with Regulations: STPs are essential for ensuring compliance with environmental regulations and standards governing wastewater discharge. Government agencies typically impose limits on the concentration of pollutants that can be released into water bodies, and STPs must meet these requirements to protect the environment and public health.

Resource Recovery: STPs can facilitate the recovery of resources from wastewater, such as energy, nutrients, and water. For example, biogas produced during the treatment of sewage sludge can be used as a renewable energy source, while nutrient-rich biosolids can be recycled as fertilizers for agriculture. Water treated in STPs can also be reused for non-potable purposes, conserving freshwater resources.

Community Livability: Effective sewage treatment contributes to the overall livability and quality of life in communities by reducing odors, pollution, and the risk of waterborne diseases. Clean waterways and a healthy environment enhance recreational opportunities, tourism, and economic development.

Disadvantages

Energy Consumption: STPs require significant energy inputs to operate pumps, aerators, and other equipment for sewage treatment processes. This energy consumption contributes to greenhouse gas emissions and environmental impact, particularly if the energy comes from non-renewable sources.

High Operational Costs: The operation and maintenance of STPs involve substantial costs, including energy, labor, chemicals, and equipment upkeep. These expenses can be a burden for municipalities and wastewater utilities, especially in areas with limited financial resources.

Sludge Management: STPs produce sewage sludge as a byproduct of the treatment process, which requires further management. Disposal or beneficial reuse of sludge can pose logistical, environmental, and regulatory challenges, particularly if proper treatment and handling procedures are not followed.

Chemical Use: Some sewage treatment processes require the use of chemicals such as chlorine for disinfection or coagulants for solids removal. While these chemicals are effective in water treatment, their use can raise concerns about residual toxicity, chemical handling, and environmental impacts.

Potential for Equipment Failure: STPs rely on complex machinery and equipment, which can be prone to malfunctions, breakdowns, and operational issues. Equipment failure can disrupt sewage treatment processes, leading to inefficiencies, discharge violations, and public health risks.

Limited Effectiveness for Certain Contaminants: While STPs are effective at removing many pollutants and contaminants from sewage, they may have limitations in treating certain types of pollutants, such as microplastics, pharmaceuticals, and emerging contaminants. Addressing these emerging pollutants may require advanced treatment technologies and additional investment.

Regulatory Compliance Challenges: Meeting regulatory requirements for wastewater discharge can be challenging for STPs, particularly in areas with stringent water quality standards or changing regulatory frameworks. Compliance may necessitate costly upgrades, modifications, and monitoring efforts to ensure adherence to regulatory limits.

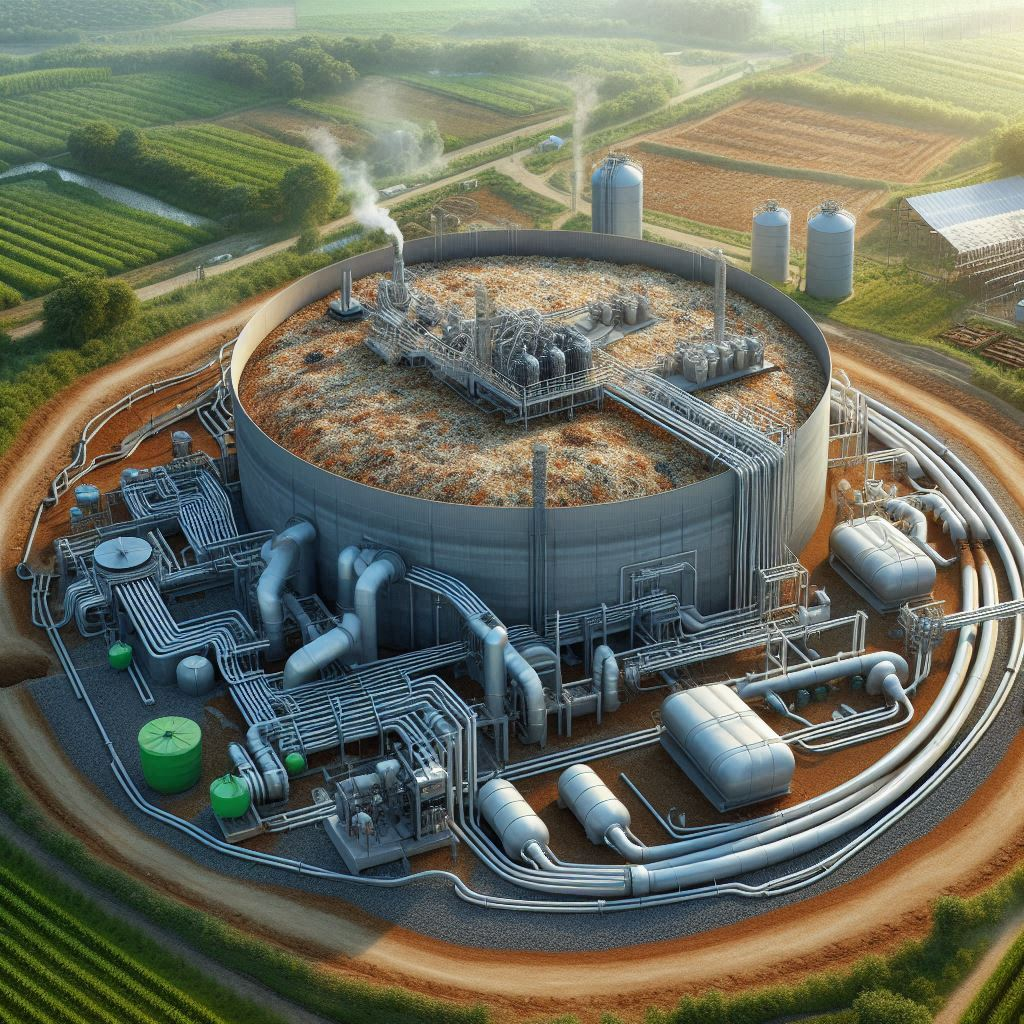

Biogas production

Sewage Sludge Composition: Sewage sludge generated during the primary and secondary treatment processes in STPs contains organic matter, including biodegradable solids, such as human waste, food scraps, and other organic materials. This organic matter serves as a substrate for anaerobic digestion, providing the necessary feedstock for biogas production.

Anaerobic Digestion Process: Many STPs employ anaerobic digestion as a sludge treatment method to stabilize the organic matter, reduce sludge volume, and generate biogas. During anaerobic digestion, microorganisms break down the organic compounds in sewage sludge into simpler molecules, primarily methane (CH4) and carbon dioxide (CO2), along with small amounts of other gases and byproducts.

Biogas Collection and Utilization: Biogas produced during anaerobic digestion is collected from digestion tanks or chambers within the STP’s sludge treatment facilities. The collected biogas can be used as a renewable energy source for various purposes, including:

- Heat and Power Generation: Biogas can be combusted in engines or turbines to generate heat and electricity for onsite use, such as powering STP operations or providing heat for sludge drying processes.

- Combined Heat and Power (CHP) Systems: CHP systems utilize biogas to simultaneously generate electricity and heat, improving energy efficiency and reducing operational costs.

- Vehicle Fuel: Purified biogas, often referred to as biomethane or renewable natural gas (RNG), can be upgraded and used as a vehicle fuel for buses, trucks, and other fleet vehicles, reducing greenhouse gas emissions and dependence on fossil fuels.

Sludge Management and Environmental Benefits: Anaerobic digestion not only produces biogas but also reduces the volume and stabilizes the sewage sludge, making it easier and safer to handle, transport, and dispose of. Furthermore, the digestion process significantly reduces the pathogens present in the sludge, improving its safety for land application as fertilizer or soil amendment, thus closing the nutrient loop and promoting circular economy principles.

Futuristic Approach

A futuristic approach involves integrating advanced technologies, innovative strategies, and sustainable practices to enhance treatment efficiency, resource recovery, and environmental sustainability.

Smart Monitoring and Control Systems: Implementing advanced sensor networks, real-time monitoring, and automation technologies can optimize STP operation, detect abnormalities, and improve process control. Artificial intelligence (AI) and machine learning algorithms can analyze data to predict system performance, optimize energy usage, and identify opportunities for process optimization.

Decentralized and Modular Systems: Future STPs may adopt decentralized and modular designs that are scalable, flexible, and adaptable to varying population densities and wastewater characteristics. Prefabricated modules, containerized units, and plug-and-play systems can enable rapid deployment, reduce construction costs, and enhance resilience to climate change and population growth.

Energy and Resource Recovery: Integrating energy-efficient technologies such as anaerobic digestion, biogas capture, and combined heat and power (CHP) systems can maximize energy recovery from sewage sludge while reducing greenhouse gas emissions. Nutrient recovery technologies such as struvite precipitation and algae cultivation can recover valuable nutrients from wastewater for reuse in agriculture or industry.

STP’s in India

- Okhla waste water treatment plant

2. K&C valley project

3. Coronation pillar

4. Kodungaiyur STP

5. Kondli waste water treatment plant

FAQ (frequently asked questions)

What is a Sewage Treatment Plant (STP)?

- An STP is a facility designed to treat wastewater from homes, businesses, and industries to remove contaminants and pollutants before releasing the treated water back into the environment.

How does an STP work?

- STPs use a combination of physical, biological, and chemical processes to remove solids, organic matter, nutrients, pathogens, and other pollutants from sewage. This includes stages like screening, sedimentation, biological treatment, disinfection, and sludge management.

Why are STPs important?

- STPs are crucial for protecting public health and the environment by preventing water pollution, reducing the spread of waterborne diseases, and ensuring the sustainable management of water resources.

What happens to the treated sewage from an STP?

- The treated sewage, also known as effluent, is typically discharged into water bodies such as rivers, lakes, or oceans after meeting regulatory standards. In some cases, the treated water may be reused for purposes like irrigation or industrial processes.

Are STPs environmentally friendly?

- When properly designed, operated, and maintained, STPs can be environmentally friendly by reducing water pollution, conserving water resources, and promoting ecosystem health. However, challenges like energy consumption and sludge management need to be addressed for optimal sustainability.

How can I ensure my STP operates efficiently?

- Regular maintenance, monitoring of process parameters, staff training, and adherence to regulatory requirements are essential for ensuring the efficient operation of an STP. Engaging qualified professionals and implementing advanced technologies can also improve efficiency.

Can STPs produce energy?

- Yes, STPs can produce energy in the form of biogas through the anaerobic digestion of sewage sludge. Biogas can be captured and used as a renewable energy source for heat and power generation, reducing the facility’s carbon footprint.

Are there different types of STPs?

- Yes, there are various types of STPs, including conventional activated sludge plants, extended aeration plants, membrane bioreactor (MBR) plants, and decentralized systems. The choice of STP type depends on factors like wastewater characteristics, treatment requirements, and site conditions.

What are the challenges faced by STPs?

- Challenges faced by STPs include energy consumption, sludge management, regulatory compliance, aging infrastructure, population growth, emerging contaminants, and climate change impacts such as extreme weather events and sea-level rise.

How can I learn more about STPs and wastewater treatment?

- You can learn more about STPs and wastewater treatment by consulting regulatory agencies, wastewater professionals, educational resources, online forums, and attending workshops or conferences on water and wastewater management.

Conclusion

Sewage treatment plants are not just facilities; they are essential guardians of our environment and public health. As we navigate the complexities of modern urban living, investing in advanced wastewater management technologies and sustainable practices becomes imperative. By supporting and improving sewage treatment infrastructure globally, we can ensure cleaner water resources, healthier communities, and a more sustainable future for generations to come.

Table of Contents

Read more about Sewage treatment plant

MTP-(medical termination of pregnancy) advantages, complications…

Go and visit dusearchit.in and get more knowledge about others topics.